China's first self-developed 2300mm vertical aluminum foil coiler successfully put into production

Aluminum foil spreader is aluminum foil processing industry "; High precision finishing" The key technical equipment in the equipment. In" Finishing" In the global development of equipment, it can be likened to high-end and high-precision modern equipment. The aluminum sheet is rolled by cold rolling machine, aluminum foil blooming mill and aluminum foil finishing mill to form a double layer of 0.03-0.005mm aluminum foil, and then cut and roll into aluminum foil material rolls required by customers through the aluminum foil slitting machine.

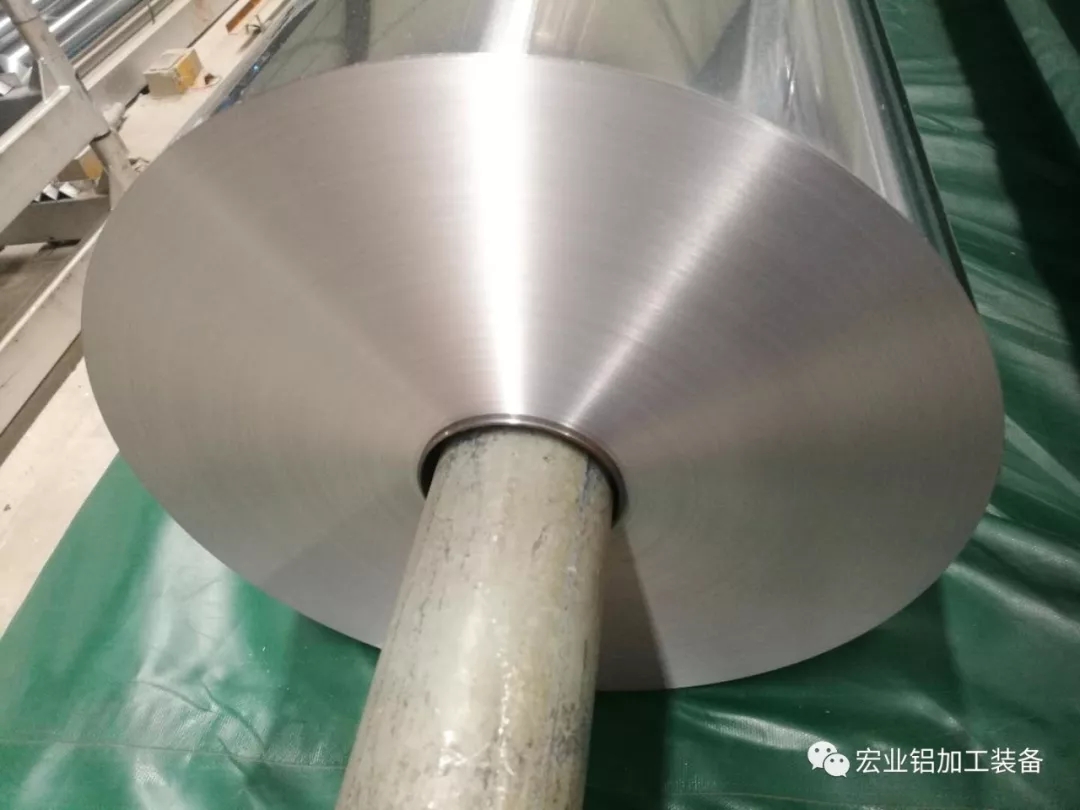

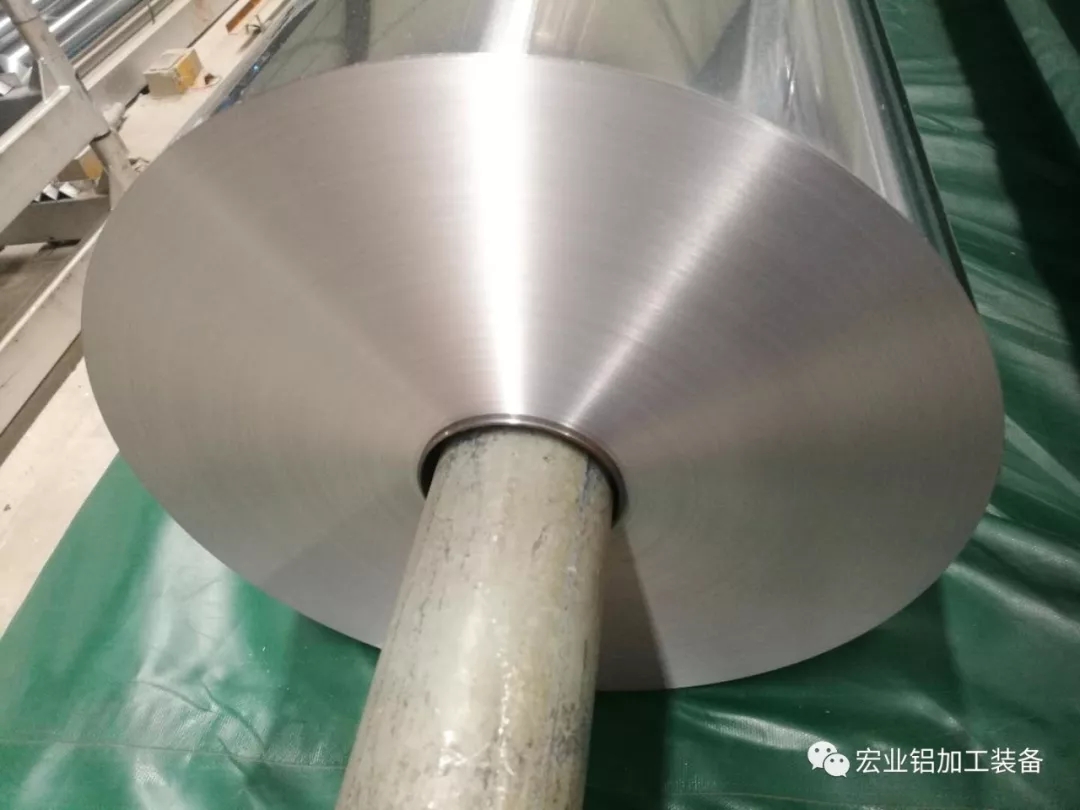

Zhenjiang Hongye Technology Co., Ltd. completely independently developed and manufactured the first set of 2300mm width aluminum foil distributor in China has been successfully put into operation in Jiangsu Dingsheng New Energy Materials Co., LTD., which successfully opened the key downstream production process for the wide double zero aluminum foil products rolled by the 2300mm aluminum foil mill provided by our company for Dingsheng Group.

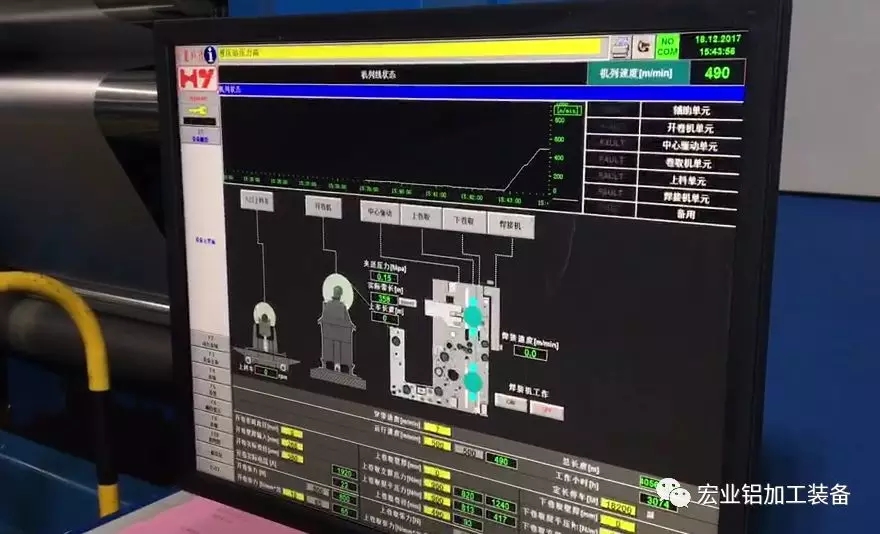

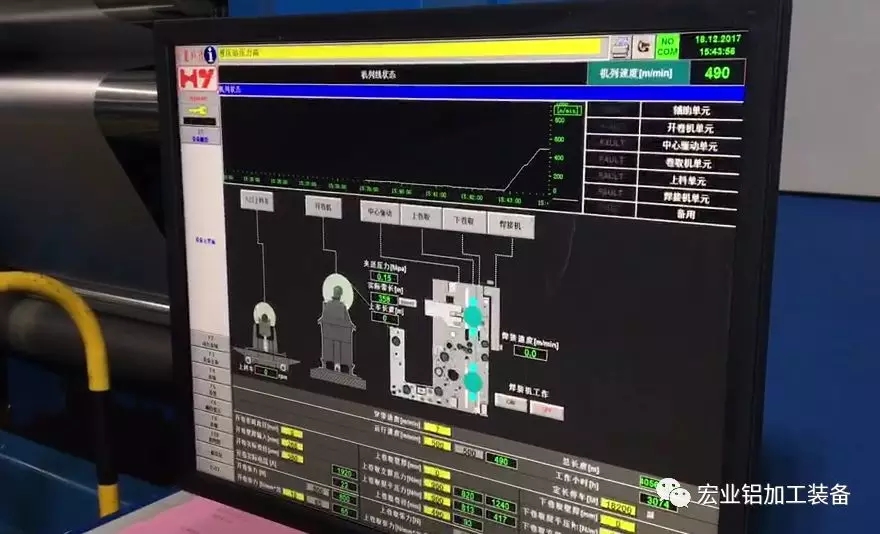

The main technical parameters of the equipment:

1. Incoming alloy: 1xxx, 3xxx, 8xxx series

2. Incoming material thickness: 2X (0.005~0.03) mm

3. Incoming material width: 1400~2050mm

4, finished roll diameter: Φ800mm (Max)

5. Maximum speed: 800m/min

At present, the equipment has been normally put into production and can stably produce double zero aluminum foil with a thickness as thin as 0.0053mm, which can fully meet the needs of domestic and foreign customers.

The first set of domestic 2300mm width aluminum foil rolling machine, which was completely independently developed and manufactured by Zhenjiang Hongye Technology Co., Ltd., has been successfully put into operation in Jiangsu Dingsheng New Energy Materials Co., Ltd., which is the 2300mm aluminum foil rolling mill provided by our company for Dingsheng Group. The rolled wide double-zero aluminum foil products have successfully opened up the key downstream production processes.

The main technical parameters of the equipment:

1. Incoming alloy: 1xxx, 3xxx, 8xxx series

2. Incoming material thickness: 2X (0.005~0.03) mm

3. Incoming material width: 1400~2050mm

4. Finished roll diameter: Φ800mm (maximum)

5. Maximum speed: 800m/min

At present, the equipment has been put into production normally and can stably produce double-zero aluminum foil with a thickness as thin as 0.0053mm, which can fully meet the needs of domestic and foreign customers.